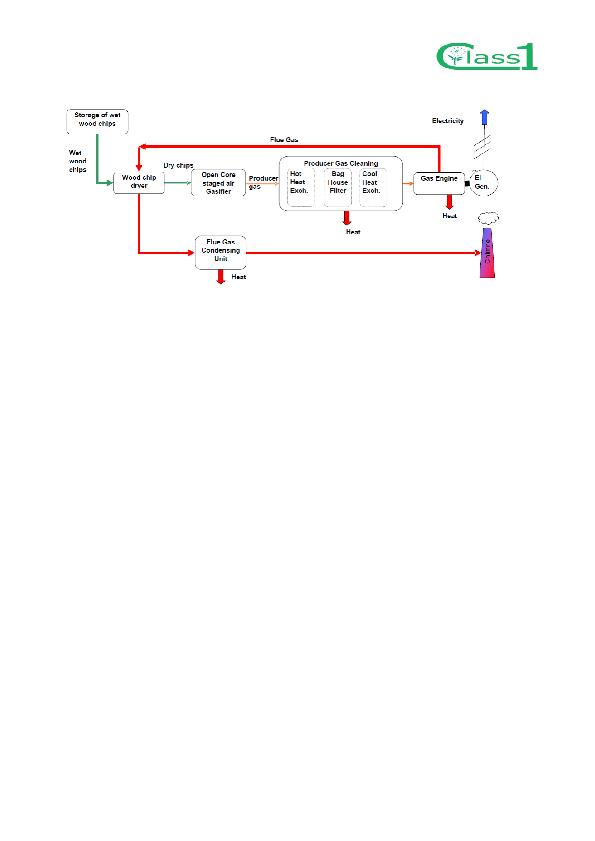

chips typically have a water content of 40-55%, wet basis. After unloading in the fuel transport system, the

wet wood chips are conveyed for drying in a rotating drier. It is heated by the exhaust gas from the gas

engine. After drying, the wood chips have a water content of 15-20 %, wet basis.

The airflow to the gasification process can be adjusted for distribution between three separate sections

within the gasifier. The temperature of the producer gas is approximately 650°C when it leaves the gasifier.

The producer is cooled immediately as it passes through a heat exchanger, which heats the air for the

gasification process.

The producer gas continues to a water-cooled heat exchanger, which cools the gas to approximately 120°C.

The producer gas is then cleaned of particles and tars in a bag house filter. After the bag house filter, the

producer gas is cooled once more, and turns out with an appropriate low temperature of approximately

60°C before it is fed to the gas engine. On its way to the gas engine, the producer gas passes a gas suction

fan, which maintains under pressure condition in the gasifier and gas cleaning section.

When preheating of the plant has been completed, the producer gas is fed to the gas engine, where it is

combusted after being mixed with air in the engine's intake system. The gas engine is coupled to an

electricity generator, which in turn is connected to the national grid.

The heat from the gas engines' cooling water and engine oil is used for heat production, while the exhaust

heat is used in the first instance to dry the wood chips. After the drying process, the energy in the moist

exhaust gases is recovered in a condensing exhaust gas cooler.

At the end of the process, the exhaust gas has a temperature of approximately 60-65°C and is saturated

with water vapour when it is led out through the chimney.